The use of gas throughout commercial and industrial processes has continued to grow throughout Ireland.

At the forefront of this is Vermac Gas. We pride ourselves on the installation and maintenance of Gas Networks in industries throughout Ireland.

The use of gas systems, especially in heavy industries comes with several risks, ones we aim to avoid with a professional approach to installation, maintenance and testing.

For your business, gas networks come with costs, safety risks, and provide much of the power and energy that you require. In this piece, we will look at Gas safety; how it can affect your workplace, and the ways Vermac can help you.

Gas Safety is Vital

To safeguard employees and operations, companies need to ensure gas safety. This is achieved by consulting and working with experts such as Vermac. We have the knowledge, experience, and products for you and your business.

Gas safety can prevent damage to property and loss of life

The manufacturing industry requires the use of a variety of machinery, chemicals, and gases that can produce dangerous and volatile situations.

If an accident were to occur such as a fire or the leakage of gas, the costs could be incredible both financially and in terms of the wellbeing of employees and the general public.

Therefore it is both your duty and ours to ensure that these accidents do not occur and that they are prevented and detected at all times.

Thankfully no large-scale accidents have occurred in Ireland in many years and at Vermac we are proud to work in an industry that safeguards against this happening.

Why Vermac?

Gas detection systems are a gateway to gas safety.

With continued advancements in gas detection technology, Vermac Gas Systems is one of the Irelands leading providers of Gas detection and safety equipment.

We have over 30 years of experience specializing in areas of heating, maintenance, burner care, and energy monitoring.

By focusing on these core areas, we aim to save our customers from breakdown costs, energy loss and costly bills that can be prevented.

Most importantly continued maintenance, testing, and calibration of your gas network will prevent accidents and damage.

Let us delve a little deeper into some of the areas we work in and the preventative measures and equipment that may be used.

The Teta EcoDet is used as part of a wider Teta Gas detection system. It is specifically designed to effectively monitor LPG concentrations in the environment. It does this through a cyclical measurement of gas in the air. Findings are then transmitted to the user via flashing lights.

The Teta Gas system is an incredible piece of equipment that we place great trust in.

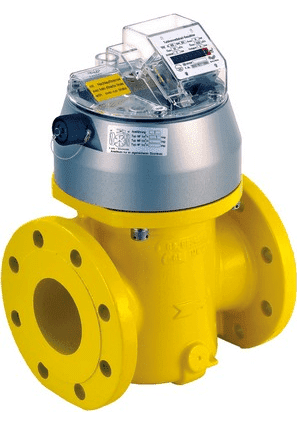

The Elgas range of volume correctors allows the user to read and gauge the usage of gases throughout their network. These units notify the need for corrections in the pressure and amount of gas being used in specific processes. This is the perfect unit to prevent gas build-ups or the wastage of excess gas.

Large scale build ups can cause explosions or severe damage to workfloors.

Burning units are used for a huge array of processes across various industries, from waste disposal to packaging and water boiling.

Such equipment can be extremely dangerous when not handled properly or when damaged. It is important to only use quality equipment supplied and maintained by professionals.

Vermac’s process

In addition to the installation of equipment, regular maintenance and testing must take place.

By using trusted suppliers and in dealing with specific industries and areas, Vermac are leaders in the field. From Tecflam to Elgas, our equipment suppliers have decades of experience within their various fields.

We can provide the maintenance and repairs on all such equipment, ensuring your business stays safe profitable and in continuous production.